Contact an installer

Contact an installer

Full project address

01

Most popular

02

Categories

Menu

close

01

Professionals

Techno Metal Post is the only North American certified helical pile manufacturer that fully welds shaft couplings together. Why is this, and what key differences/advantages does this type of coupling have?

The short answer is that they are stronger than bolted couplings. Please read on for more details-

The buckling of columns is a concern in structural engineering. Imagine pressing down on a yardstick or slender rod with your hand, which initially carries some load. Then, at a certain point, the slender column will deform sideways near the middle of its height and become unstable. This failure mode is called buckling.

Helical piles are slender columns in the ground. Usually, the ground will prevent buckling by laterally bracing the shaft throughout its length, however, this is not always the case. Occasionally helical foundation shafts extend up into the air, through water, are placed into fluid, or very soft soil. Sometimes the fluid soil zone can be well below the ground surface, and whenever the shaft is not fully braced by soil, buckling should be considered. This is one reason why a fully welded shaft is better than a bolted shaft.

Bolted couplings will have some slack, or freedom to move laterally and cannot be manufactured perfectly snug or tight. Bolt holes are larger than the bolt diameter to promote easier installation, and coupling sleeves are also oversized for the same reason. This manufactured slack in the couplings must be accounted for in the buckling design. Fully welded couplings, which do not have any slack, are stiffer and stronger than bolted couplings. These features are appreciated by engineers and building officials alike.

What about weld inspection? Yes, it’s true that building codes do recommend that welds are inspected. This is also true for bolted connections. One key point is that Techno Metal Post's coupling welds are proof-tested for strength during installation.

The stress placed on the weld during installation is greater than the stress the weld will see once the structure is built. Techno Metal Post's evaluation report IAPMO ER 481 even says so.

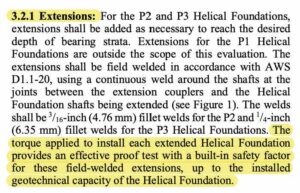

IAPMO ER 481 Section 3.2.1

This section of IAPMO ER 481 has been successfully used to show building officials why weld inspections are not needed. If the weld is strong enough to twist the pile into the ground, it will be strong enough to resist the load it was installed to.

What about weld corrosion? In the case of bare steel, weld strength calculations take into account a sacrificial corrosion thickness, in the same way as for the pile shaft. If the shaft is hot-dipped galvanized, this galvanized coating adjacent to the bare steel weld will protect the weld. This works similarly to Techno Metal Post’s sacrificial anodes that are applied to bare steel shafts. When using a galvanized steel pile, it is recommended to apply a coating of zinc-rich paint to the weld before you twist it into the ground, as an added precaution.

As always, reach out to the engineering team if you have any questions.

SCREW PILES

WITH TECHNO METAL POST, IT'S FAST AND EASYTechno Metal Post makes life easier for anyone with a construction project that requires a foundation in almost any type of soil.